Imagine perfecting the tech behind ultra-thin foldable screens or AR glasses without damaging them during quality checks. That’s exactly what researchers in China just achieved! 🎯

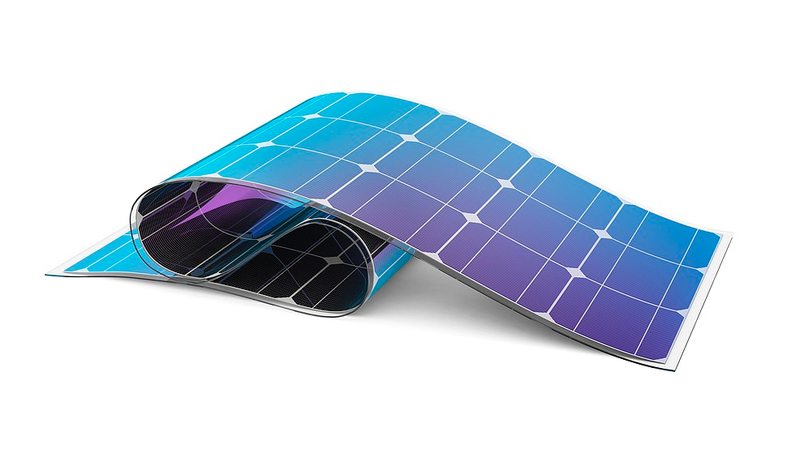

A team at Tianjin University has developed a non-destructive testing method for micro-LED wafers – the tiny powerhouses behind next-gen displays. Led by Professor Huang Xian, their innovation uses flexible 3D probes softer than a butterfly’s touch (literally 0.9 megapascals pressure! 🦋) to inspect wafers without scratches or false alarms.

Why does this matter? Micro-LEDs are the holy grail for future gadgets, but current testing methods either wreck surfaces or miss defects. Huang’s team solved both issues: "Our probes last a million cycles and keep wafers pristine – like giving them a spa treatment instead of a stress test," he joked in Nature Electronics.

The breakthrough comes with a custom measurement system that could turbocharge production of flexible displays and even biophotonics devices. 💡 Already in commercialization talks, this tech might soon supercharge China’s micro-LED industry while giving global tech giants a new quality-control blueprint.

Next stop? Probably your future smartphone screen. 📱✨

Reference(s):

Researchers advance non-destructive testing of micro-LED wafers

cgtn.com